We put our extensive experience in molding at the service of the customer, suggesting technical solutions aimed at achieving maximum production efficiency.

Founded in 2007, ACG F.lli Manca S.r.l. carries forward the tradition established in 1985 by Ve-Ma Plast.

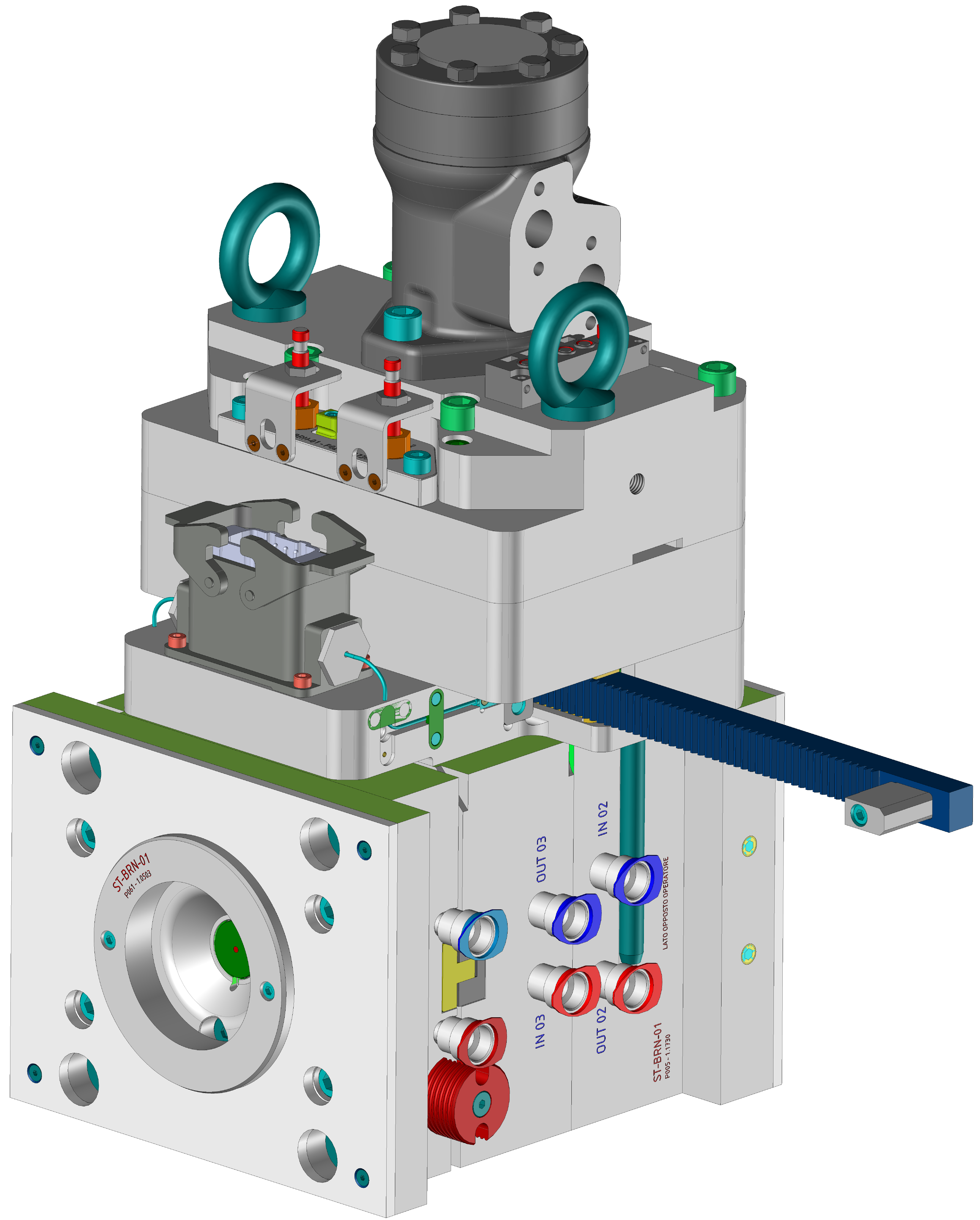

Our company specializes in plastic injection molding, combining decades of experience with continuous investments in advanced technology and innovation.

This enables us to deliver precisely what our clients require, with unwavering quality and attention to detail.

What do we offer? A complete service that begins with your concept and ends with the delivery of the finished product to the market.

We manage every phase of the product industrialization process, addressing every detail with precision.

With extensive experience in molding, we assist our clients in the initial design phase, material selection, and full-scale production.

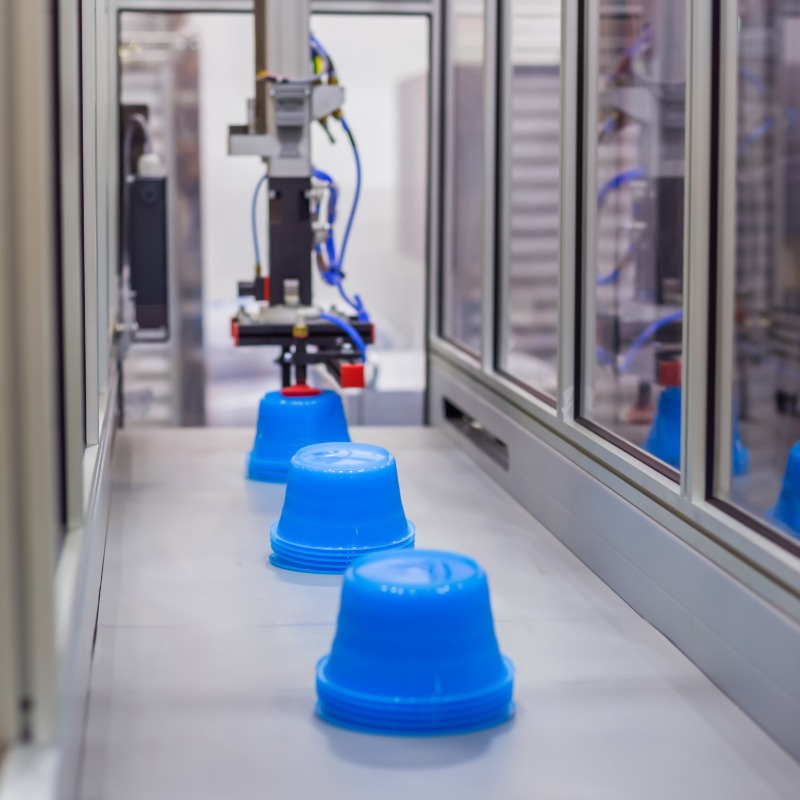

Our production department operates 24/7 to meet your needs.

We also support clients in the distribution phase, offering customized packaging and direct shipping to major retailers, ensuring a comprehensive and timely service.

How do we achieve efficiency? With a cutting-edge and continuously evolving machinery fleet, supported by a centralized system that enables real-time production planning and management.

We closely monitor production to ensure alignment with client agreements, leveraging advanced measurement and control systems at every stage.

Our commitment to continuous investment in technology and innovation has created a versatile and interconnected production environment, capable of meeting the demands of diverse industries.

While technology drives our processes, our team remains our most valuable asset and the cornerstone of our success.

The cosmetics industry demands innovation, exceptional quality, flexibility, and meticulous attention to detail, delivering products that enhance beauty while ensuring customer satisfaction.

We ensure speed, precision, and strict adherence to technical specifications, providing tailored solutions for every need.

We develop tailored control plans for each product in collaboration with the Client, ensuring compliance with the required standards.

Upon request, we can perform non-contact measurements on printed parts to eliminate subjective errors and provide a detailed dimensional report, ensuring:

We adopt an ISO 9001 Certified Quality Management System, ensuring reliable, customer-focused processes. This approach guarantees excellence, strict control, and continuous improvement to meet and exceed expectations.

Sustainability is increasingly central to our company. We are implementing a dedicated management system that integrates sustainability criteria throughout the supply chain, evaluating decisions based on long-term environmental, social, and human impacts. We collaborate with EcoVadis™, a leading platform for corporate sustainability assessment, to ensure high standards and transparency. Our goals include reducing emissions through optimized energy consumption and fostering a safe, sustainable work environment for our team.

Get in touch with us